Watson Metal Master's Podcasts

Looking for a great career? Check out our podcasts with President Bill Schahuber and learn more about our company

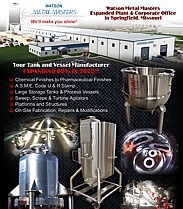

Watson Metal Masters Services You Can Trust

Stainless Steel

Tank Fabrication

Engineering

Services

Stainless Tank

Field Repair

Glass Bead

Blasting

What Our Customers Say

Afton Chemicals

Great CompanyThere are several stainless steel tank manufactures out there, particularly in Springfield, MO. But, we have found Watson Metal Masters to be more responsive and professional than others we've dealt with.

Fleischmann's Vinegar

Repair Masters!We had several tanks that were damaged in a recent hurricane. We contacted Watson Metal Masters to see if they could help. Boy did they! Tremendous response time. We were back in business right away.